Description

Specification

Video

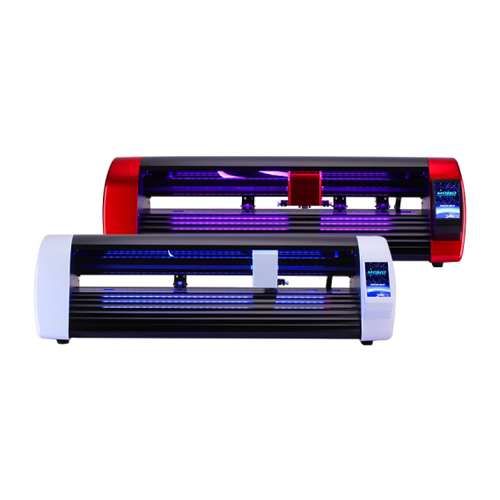

Description

◇ Automatic knife depth adapting system can help easyly find the best knife depth value as it changes to new or different knife.

◇ It can continue to cut 1 to 10m paper . During the process of cutting, it can suck the paper automatically.

◇ Intelligent controller supports the long distance data transmission. It is quiet when the machine is working

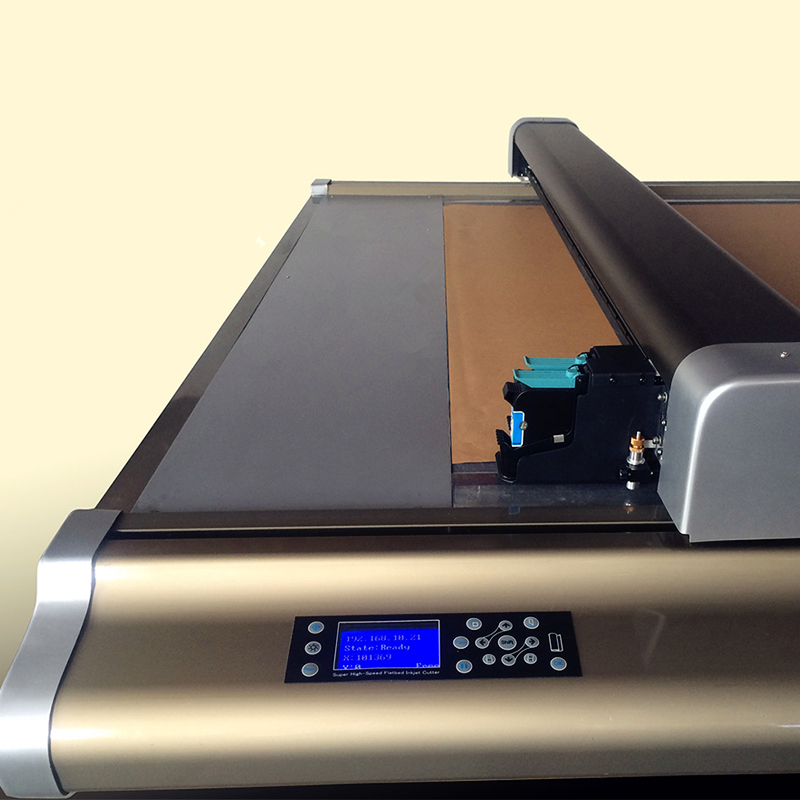

◇ Automatic feeding paper system ensures accuracy feeding . The operation is easy. The independent feeding rack can bear 50kg paper.

◇ Standard equipped adsorption platform and low noise air pump.

Specification

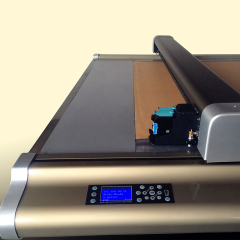

| Model | M-1209A | M-1509A | M-1512B | M-1812B | M-1816B |

| Max. Cut Width | 90 cm | 90 cm | 120 cm | 120 cm | 160 cm |

| Max. Cut Length | 120 cm | 150 cm | 150 cm | 180 cm | 180 cm |

| Max. Cut Speed | 90 cm/s | 90 cm/s | 90 cm/s | 90 cm/s | 90 cm/s |

| Gross Weight | 280KG | 300KG | 420KG | 560KG | 700KG |

| Cutting Accuracy | 0.1mm allowance. | ||||

| Max. Cut thickness | 2mm for Paper Board, 1mm for the PVC etc. | ||||

| Cut Curve | Auto smooth and optimized technology for the curve, it can cut more accuracy. | ||||

| Files formats | HPG, HP-GL and GP-GL, Directly driver by Autocad etc. | ||||

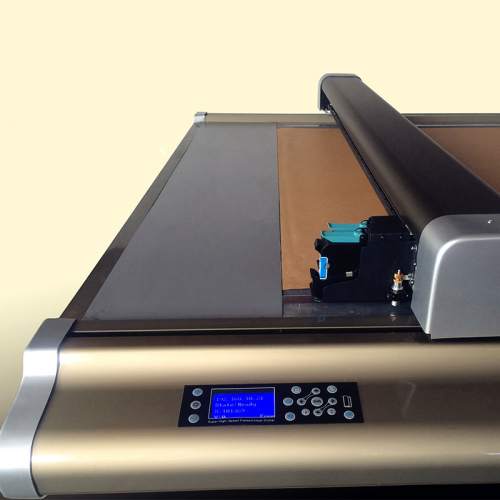

| Inkjet/Cut Heads | Double heads design: Two HP45 cartridges and 2nd Cut-head to cut. | ||||

| Inkjet/Blade Type | Knife type: Normal knife to cut 1mm paper board: the Hp45 Cartridges to be working by free maintenance |

||||

| Cut Materials | 60gram to 800gram weight paper board, and normal 0.1-0.2mm plastic board, man-made leather for home furniture etc. industry. |

||||

| Materials sorption | Low-noise Vacuum System With Powerful Air Pumps as standard | ||||

| Power | Cutter: 800W, AC 220±10%,50HZ; Air Pump:1500W, AC 220±10%,50HZ; | ||||

| Temp&Humidity | Temp: 0℃-45℃, Humidity:20%-60% | ||||

| Port | Super LAN Port | ||||

| Main Shaft | Control by Advanced Servo control system, Servo motor as Optional. | ||||

Video

Send your message to us