Laser beam path adjustment

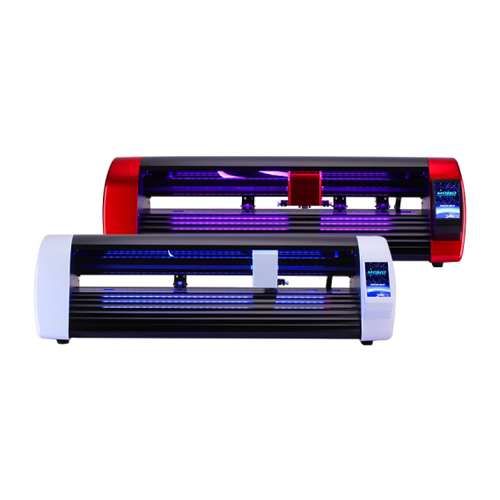

Dear Customer, thank you for purchasing and using MOMO laser cutting plotter machine. In order to ensure that you can use the energy of the laser more efficiently, the laser beam path of the machine needs to be adjusted accurately.

The laser beam path adjusting device is specifically designed according to the structural features of this machine. It works in a different way from the laser beam path adjusting function on the laser machine. Without any spring tension adjustment knob, the laser beam path adjusting device makes adjust point less, dimming simpler, and the adjusted laser beam path more stable.

Possible causes of minor deviations of the laser beam path are:

1. The stress generated in the installation and assembling process after transportation

2. The stress generated in the moving process

3. The stress generated by external force.

Laser beam path deviations characteristics:

laser intensity is strong at the right end, and gradually weaker to the left end.

Possible causes of deviation of the laser beam path :

when the laser head is moving from right to left, the deviated laser beam path will caused gradually deviate ,laser beam energy reached to the final reflector on the laser head (the third reflector) becomes less and less.

The laser beam emitted from the laser tube gets focused after going through three reflectors.

Laser beam path inspection and adjustment method:

1. The first reflector will not cause laser beam path deviation and has been adjusted at the factory manufacturers. Customers can not adjust the first reflector;

2 .The third reflector (on the laser head) is fixed. Customers do not need to adjust the third reflector;

3. Only the second reflector can be adjusted for checking and correcting the laser beam path:

1> Use a small piece of thin double-sided adhesive paper to cover the laser beam Import hole at the upper right portion of the laser head;

2> In the offline mode, use the arrow keys"→" (or simply press the "reset" button) to move the laser head to the right side of the machine;

3> Turn the laser current down (with light), press the "Test" button , and then use the laser beam to burn a black dot on the double-sided paper (the first dot);

4> On offline mode, use the arrow keys "←"to move the laser head to left side of the machine, press "Test" button, and then use the laser beam to burn another black dot on the double-sided paper (the second dot);

5> The first dot is always accurate If the second dot coincides with the first dot, it means that the laser beam path is completely accurate;

6> If the second dot is deviate from the first dot, please open the cabinet door on the right side, adjust the hexagonal screws (move the second dot up or down) or Phillips screws (move the second dot forward or backward) on the second reflection device, and then press the "Test" button, until the second dot coincides with the first dot;

7> Till now, laser beam path adjustment is finished. Remove the double-sided adhesive paper.