Description

Specification

Video

Optional configuration

Description

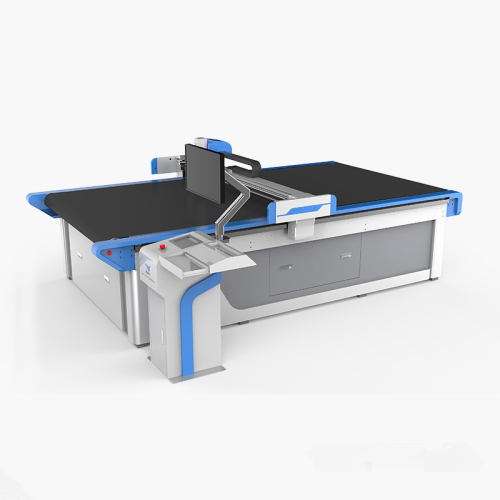

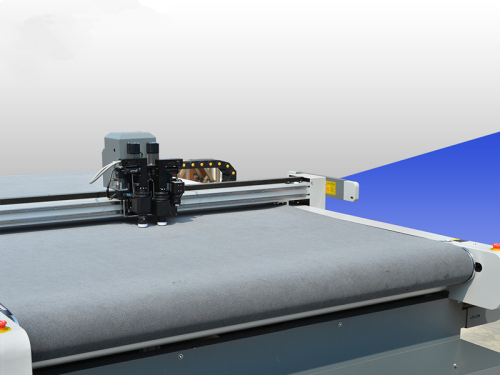

◇ Electric shock and head are strong,and vibration frequency is high,which can up to 25000 times per minute.

◇ Cutting machine transmission system adopts imported gear, rack.The cutting precision achieve zero error.

◇ Using Servo-motor from Mitsubishi; computer control the depth of the knife.

◇ There has vibration knife, drag knife, draw tools and optional half knife, cutter, slotted knife, knife, indentation knife and other tools. It can achieve the line drawing, cutting, dotted half cut and full cut and milling cutter cut, V-CUT slot, milling, pressing wheel, indentation.

◇ Fully automatic camera positioning function: automatic positioning and cutting the printed materials. Without manual positioning, it can be cut out the outline.

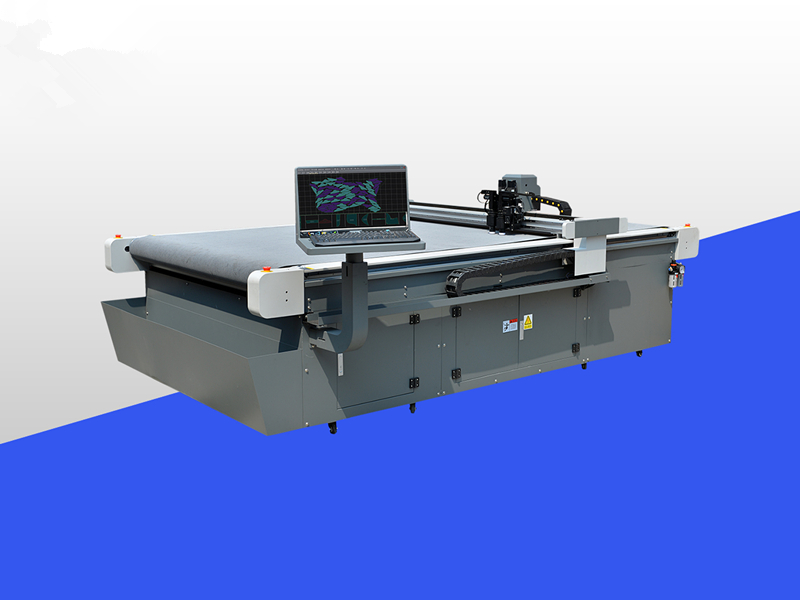

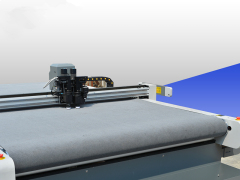

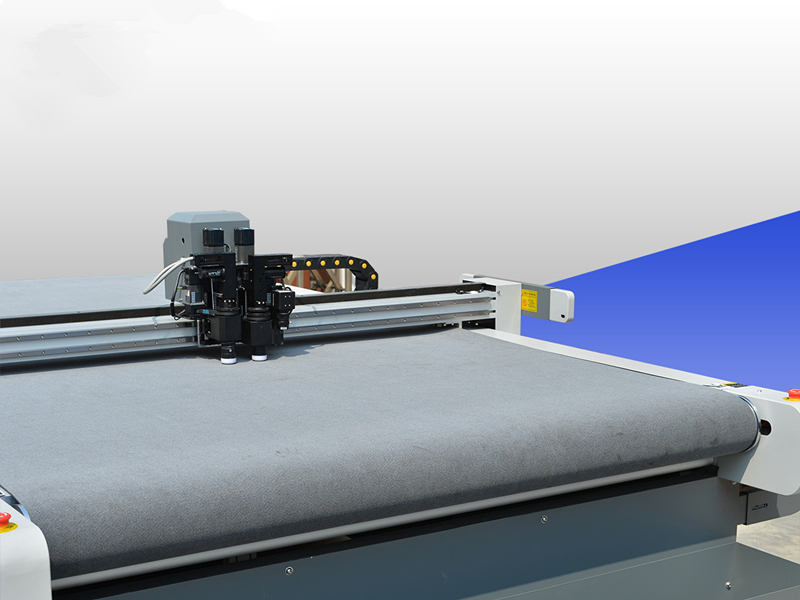

◇ Adopts the advanced rolling table, and the platform width can be customized; the cutting length is not limited.The vacuum suction can suck small sample sheet with super wind.

◇ The completely independent research and development of computer control system supportthe remote teaching, remote maintenance, remote upgrade, let the customer with more peace of mind.

◇ Any CAD software can be connected. It is widely used for plotting and cutting industries and sectors like garment, shoe making, cases, handbags, lighting fixtures, advertising , self-adhesive and color box packing.

◇ The charging rack can be equipped as option. And auto feeding device.

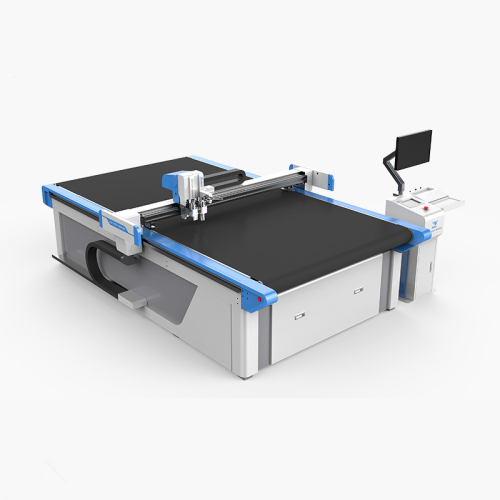

◇ Cutting machine transmission system adopts imported gear, rack.The cutting precision achieve zero error.

◇ Using Servo-motor from Mitsubishi; computer control the depth of the knife.

◇ There has vibration knife, drag knife, draw tools and optional half knife, cutter, slotted knife, knife, indentation knife and other tools. It can achieve the line drawing, cutting, dotted half cut and full cut and milling cutter cut, V-CUT slot, milling, pressing wheel, indentation.

◇ Fully automatic camera positioning function: automatic positioning and cutting the printed materials. Without manual positioning, it can be cut out the outline.

◇ Adopts the advanced rolling table, and the platform width can be customized; the cutting length is not limited.The vacuum suction can suck small sample sheet with super wind.

◇ The completely independent research and development of computer control system supportthe remote teaching, remote maintenance, remote upgrade, let the customer with more peace of mind.

◇ Any CAD software can be connected. It is widely used for plotting and cutting industries and sectors like garment, shoe making, cases, handbags, lighting fixtures, advertising , self-adhesive and color box packing.

◇ The charging rack can be equipped as option. And auto feeding device.

Specification

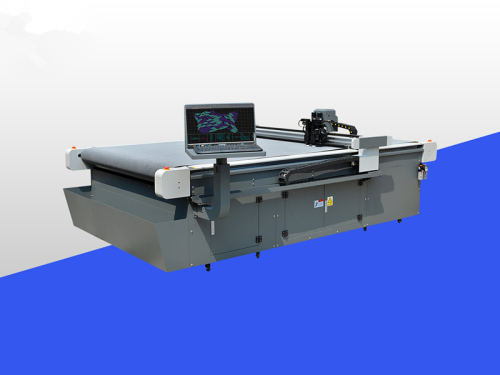

| Model | M-ASF-1410 | M-ASF-1813 | M-ASF-2516 | M-ASF-2520 |

| Cutting area | 1400mm*1000mm | 1800mm*1300mm | 2500mm*1600mm | 2500mm*2010mm |

| Overall dimension | 2300*1700*1220mm | 2700*2000*1220mm | 3400*2300*1220mm | 3400*2710*1220mm |

| Operation properties | Computer operation and cutting machines can be used simultaneously for quick data transmission ,can be capable of continuous operations | |||

| Cutting speed | Maxi 1500mm/s | |||

| Cutting thickness | 0.2-60mm | |||

| Cut materials | Corrugated materials, sponge and foam board, lvory cardboard, gray paper, corrugated paper, plastic sheets, composite materials and leather materials | |||

| Number of pens | 8 different groups of draw pens, half blades, full blades and pressure wheel setup | |||

| Positioning device | Automatic camera positioning | |||

| Method for fixing paper | Vacuum absorption | |||

| Cutting accuracy | ±0.2mm | |||

| Repeat accuracy | ≦0.05mm | |||

| Minimum circle | ≧5mm diameter | |||

| Transmission interface | Ethernet port | |||

| Format compatible | AI software, Autocad, Coreldraw and all box software | |||

| Direcive system | HP-GL and GP-GL | |||

| Digital control panel | Liquid crystal display and contact button | |||

| Transmission materials | Gear-rack drive | |||

| Supply voltage | AC 220V 380V ±10%,50HZ | |||

| Motor type | adopts servo motor | |||

| Vibration blade | Vibration cutter head motor at 25000rpm | |||

Video

Optional configuration

A: Conveyor table + spindle + 4 axis + Oscillating knife + pen

B: Conveyor table + spindle + 4 axis + (synchronous rotation) presser + Oscillating knife + pen

C: Conveyor table + spindle + 6 axis + V cut + independent presser + half cut head + Oscillating knife + pen

D: Conveyor table + spindle + 7 axis + Oscillating knife + V cut + independent presser + half cut head + pen

Send your message to us